We develop advanced sound reduction solutions for each customer’s needs. It all starts with a preliminary phase in which we acquire information from the customer and analyze the available data. We carry out a preliminary numerical simulation of the metamaterial solution. The preliminary phase is free.

Diagnostics for metamaterial development, identification of significant frequencies on a physical sample.

Metasolution Prototyping.

Industrialization and certification of the Metasolution (if new).

We are happy if there are solutions that solve the problem. If Metasolutions are developed with the customer, IP strategies are discussed in steps 1 and 2.

To get into practice, below we report a case study that shows how we operate, from design to development of the solution through the use of metamaterials. The challenge reported in this area was to reduce the noise of a Vacuum Cleaner.

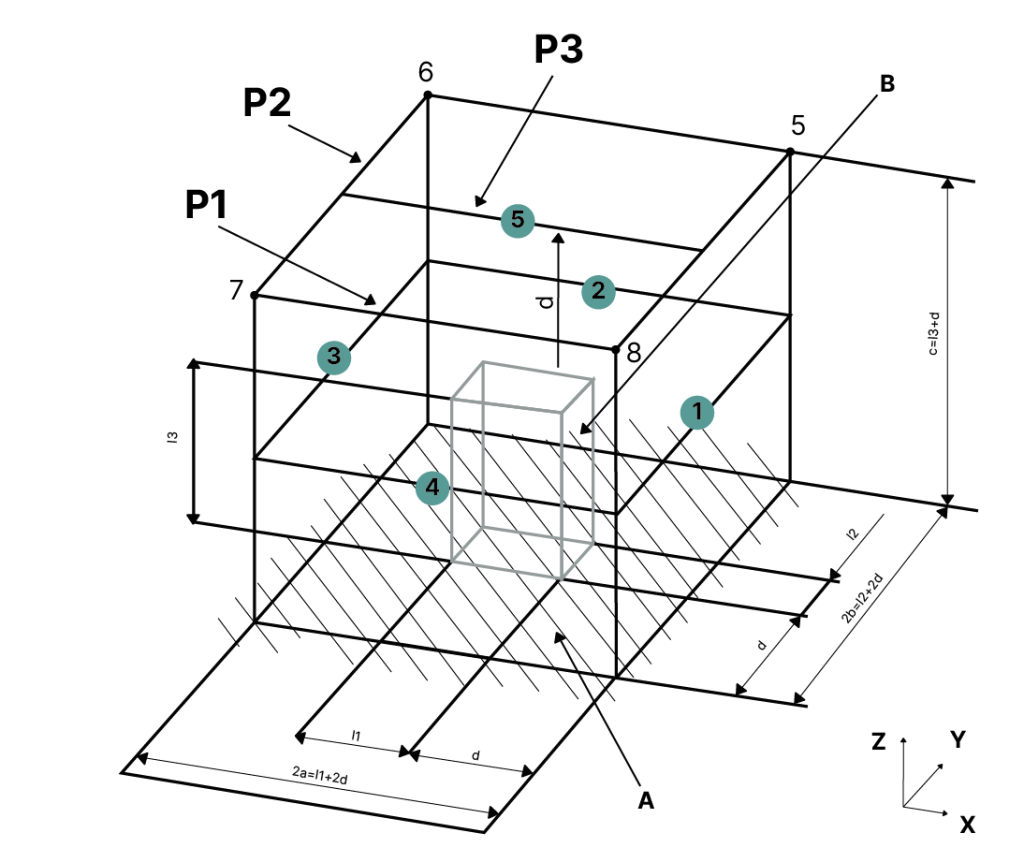

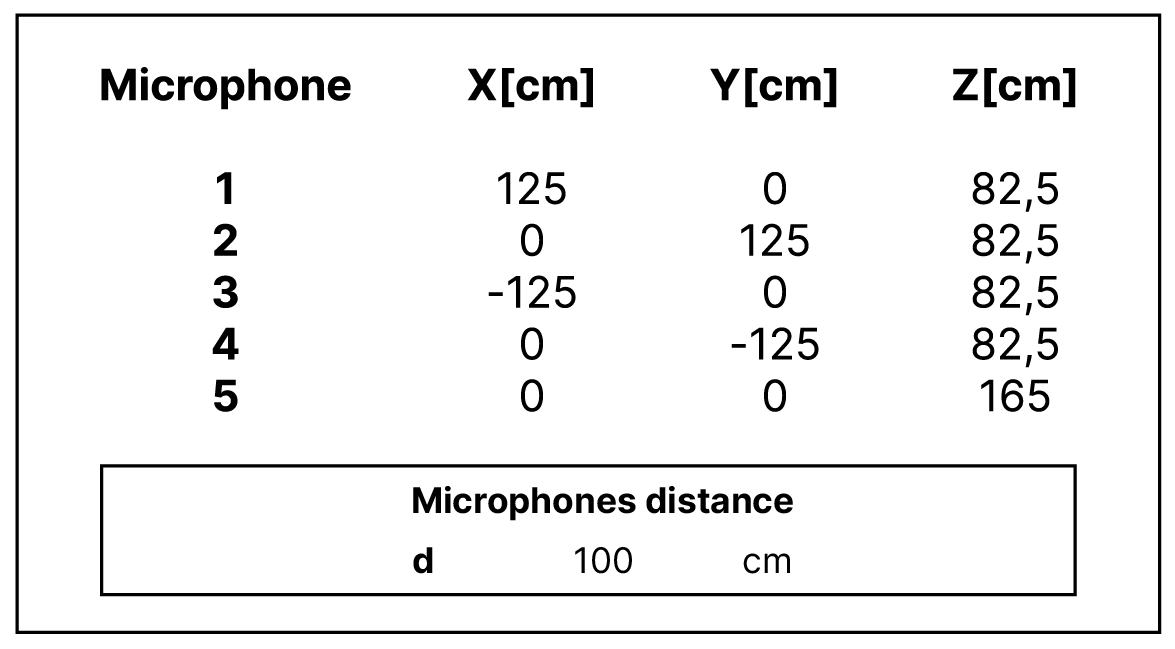

In the first phase we concentrated on a measurement through microphones positioned in different points to understand what the source or sources of the acoustic disturbance were.

• We used a silencer to exclude the noise from the extractor’s air outlet.

• The measurement was performed in “normal operation mode” or under the conditions of normal use.

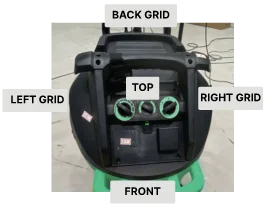

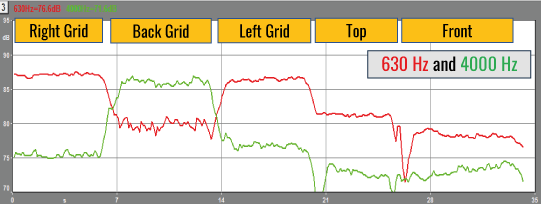

From the measurements carried out we identified the points from which the acoustic disturbance came, in terms of frequency and decibels. The work carried out allowed us to understand the extent of the acoustic disturbance coming from each single point, to understand where it was appropriate to act.

Our solutions applied to the Vaccum cleaner for sound reduction with results ranging from a reduction of 2dBA to 4dBA.

• MetaFan on backgrid – Tuned @4000Hz 2dBA improvement

• MetaFan on lateral grids – Tuned @630Hz 4dBA improvement

We will reply to you as soon as possible. If you prefer to be contacted by telephone, leave yours contact details and we will call you as soon as possible from Monday to Friday from 9:00 to 18:00.